A lift table is a type of handling platform that is used for lifting, lowering, or bringing up some load to a certain height. The lifting platform can be either mobile or stationary. It can deal with loads that weigh just a few kilos and up to several tonnes. In terms of height, some of the lift tables can go as high as several meters.

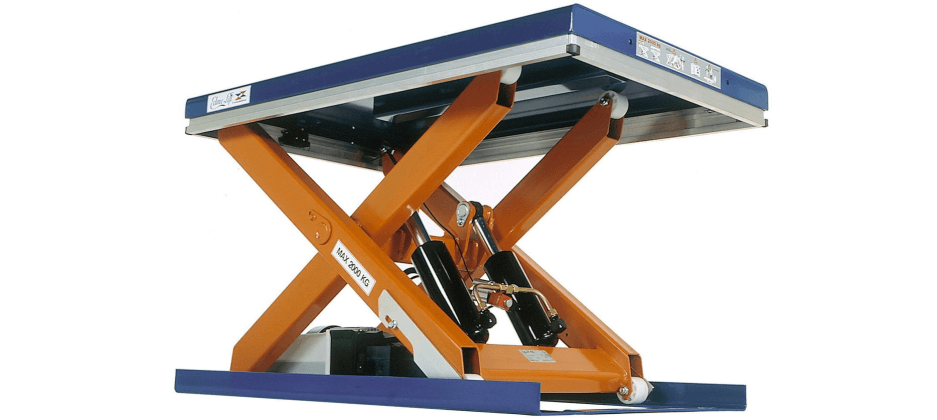

Lift tables rely on the so-called scissor or column type of technology. Both technologies are commonly used in garages and workshops of various kinds.

How to Choose a Lift Table?

Thanks to their versatility, lift tables are used in all sorts of working environments. To select the best one, one needs to consider three primary factors:

- Technical characteristics

- Type of Technology

- Mobile or Stationary

Technical Characteristics

Load Capacity & Dimensions

The bigger the lift table dimensions, the bigger its load capacity will be. Lift tables come with a load capacity ranging from 100 kg to 4 tonnes.

Load Lifting Height

That includes both the minimum height at which something can be loaded, as well as the maximum height that can be reached while the lift table is fully loaded. Some lift tables can go to a floor level so that you can push the workload onto its table. As far as the height, some lift tables can reach up to 10 meters. However, keep in mind that the higher the reach, the steeper the price of the lift table will be.

Cycles per Hour

This refers to the frequency of use of the lift table without stopping.

Lifting Time

This refers to the time the lift table needs to unfold.

Type of Technology

Column Type

They are best suited for long handling tasks and are somewhat less stable than scissor lift tables.

Scissor Lift Tables

They are quite sturdy and stable. Scissors tables can be single, double, or tandem.

Tilting Lift Tables

The deal with these lifting tables is that they can be tilted at a certain angle. Usually, that angle range is from 5° to 40°. The biggest tilting lift tables can lift to 3 tonnes of loads.

Stationary or Mobile?

Whether you need one, you can move around, or a fixed one depends on your intended use.

- Stationary lift tables are ideal for repetitive and fixed workstations. Just make sure you buy it from a reputable stationary Lift Table china supplier that holds all the necessary quality certificates.

- Mobile lift tables are common for workplaces where the workload takes you on different locations within your premises. They come in various sizes and with different characteristics.

Operation Method

There are electric and manual lift tables. The manual lift tables are good for bear loads no greater than a tonne. They come with wheels and brakes, which gives them good maneuverability. Then there are electric lift tables that are controlled by three buttons and can carry up to four tonnes.

In Conclusion

Now you know what’s at your disposal, which types of lift tables are on the market, their main characteristics, and pretty much anything in between. So once you take into consideration the specific needs of your business, the choice becomes more obvious.