Jewelry casting has evolved over the years with technology. The first method was sand casting. By the beginning of the 20the century, lost wax type of casting became the option due to its cost-efficiency, reliability, and consistency. Lost wax ptocess of casting made jewelry making simple. A jewelry casting machine has several applications, as indicated in this blog post.

Accordingly, there are many machines, tools, and supplies that can make jewelry casting more straightforward. For sand-cast, you can use the lost wax technique, which is the fastest and easiest way. Accordingly, there is centrifugal casting pressure casting, vacuum, and casting induction casting, which are all lost wax-casting techniques.

These techniques are used to cast metals like gold, platinum, silver, copper, brass, or other alloy.

Below are some applications of jewelry casting machines

1. Wax casting

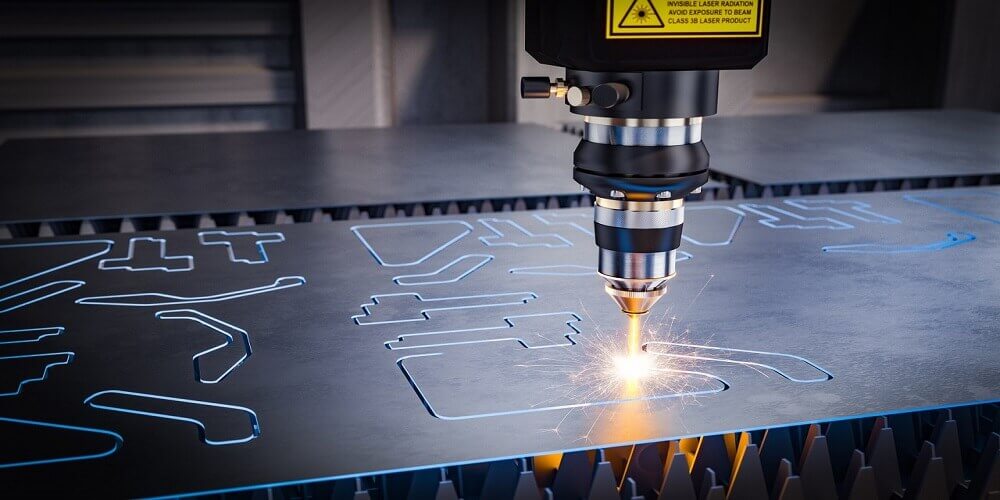

Jewelry casting machines can be used to make pieces of jewelry through the wax casting technique. Wax casting is a method applied by artists to create sculptures of any size. In this case, a wax model of any object is used to create a mold. Molten metal is then poured into the mold to create a sculpture. This jewelry casting technique has been used for ages.

2. Application in medicine

Jewelry casting machines have been used in the past to create pieces for dental works in hospitals. The need for jewelers to create a small jewelry setting has led to the medical adaptation of jewelry casting machines for dentistry purposes.

3. Making protective layers

Using jewelry casting machines with wax casting technique has been adopted for many reasons. It is easy to create custom settings and mounts for freeform stone and protective designs using soft gems like dioptase and opal. Additionally, jewelers can use rubber molds of original pieces to make wax models for protective copies.

4. Aesthetics

As the name suggests, jewelry casting machines are used to produce fine forms of jewelry. Most artists use these machines to explore their creativity by creating items that enhance beauty. You have undoubtedly used jewelry before as part of your dressing.

For instance, many people love designer rings and pendants. These materials are molded using jewelry casting machines and a wide variety of methods, as listed in this article.

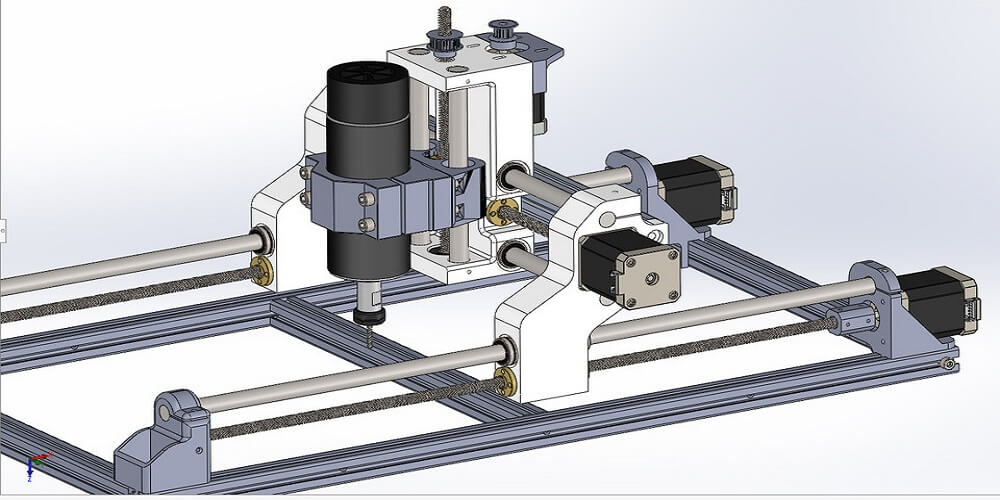

Types of jewelry casting machines

The two most used types of jewelry casting machines are centrifugal casting machines and vacuum casting machines. A centrifugal casting machine used the metal weight and centrifugal force to fill a mold. In contrast, vacuum casting machines use a vacuum to suck the molten metal into a mold.

These methods require force to overcome the molten metal’s surface tension and prevent the metal from forming a blob. If the desired model is delicate, more force is required to push the molten metal into a tiny mold.

Final word

Jewelry making using jewelry casting machines and a wide array of jewelry casting techniques is cost-efficient, especially when producing custom designs. The consistency and reliability of these machines make them popular in many industrial applications. Various applications require a specific casting method. Accordingly, the industry has devised a lot of them. For instance, jewelers can use water casting, steam casting, wax casting, sand casting, tufa casting, and Cuttlebone casting.