CNC milling is a technique that utilizes automatic controls and special cutting tools to continually reduce the size of a workpiece. The main purpose of this process is to create custom-designed parts.

Materials that can be machined include glasses, metals, and plastic. For every machining process, CNC parts play an important role.

CNC Milling Machine Considerations

Before embarking on any machining process, there are some factors you must consider. These factors will help you decide which Milling machine is best suited for your purpose.

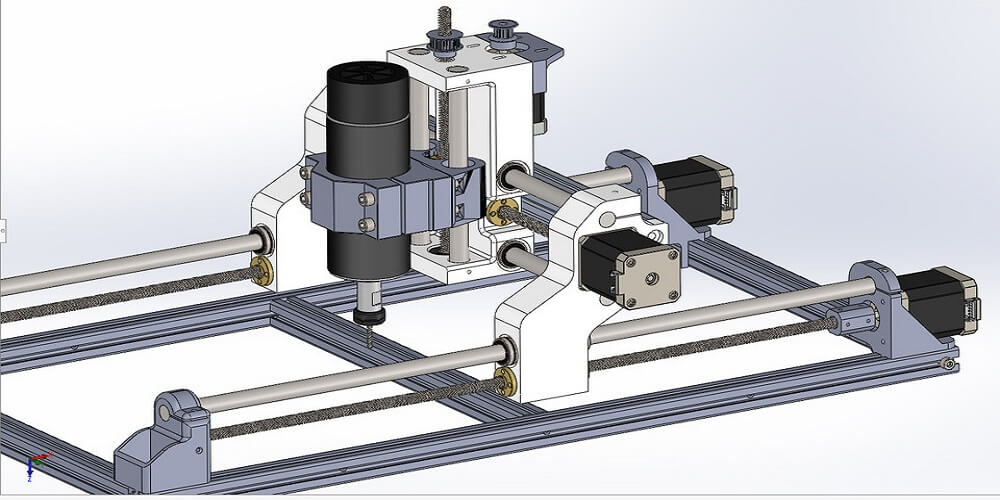

Milling machines are grouped into two types. The vertical machine configurations and the horizontal machine configurations. Milling machines can also be categorized based on their number of axes.

One of the major differences between these two types is the position of the machine spindle. Spindles are vertically placed in the vertical milling machines while they are horizontally placed in the horizontal milling machines.

Controls for both types of machine whether vertical or horizontal depends on the sort of machine used. For instance, some machine’s spindle and worktable are flexible while others are not.

Before you decide to go horizontal or vertical, ensure that your choice must meet the requirements of the milling operations. For instance, be sure it can accommodate the number of surfaces to be milled.

It must also accommodate the shape and size of the surface to be milled. Horizontal milling operations are mostly ideal for heavier materials. For lighter materials, operators normally utilize vertical milling operations.

No of axes is another factor to consider while choosing a milling machine. Most of the CNC milling machines widely available are designed with 3 to 5 axes.

The X and Y-axis represent horizontal movement while the Z-axis represents vertical movement. The fourth axis is known as W-axis. It is used to show diagonal motion through a vertical plane.

Horizontal motion is possible in the X and Y direction. But with the invention of new models, a lot of improvements have been made.

Material Considerations

Even after considering the milling machine, one must also consider the materials to be used. With the use of CNC milling operation, a large variety of materials can be machined.

Some of those materials include Elastomers, Glasses, Plastics, Composites, and Ceramics.

Just like in every other process, there are some factors to consider before choosing a milling application material.

Some of the factors to be considered include

- The hardness of the material

- Temperatures resistance

- Chemical resistance

- Tensile strength

- Cost-effectiveness

All these determine whether a material is suitable for a machining process or not. Considering the cost-effectiveness help one determine whether the process is feasible financially or not.

Alternatives: Other Machining Processes

Even though CNC milling is suitable for most machining processes, it is not suitable for all. It might also not be cost-effective which is why alternatives are provided.

Other conventional machining processes include drilling and turning. In Drilling, multi-point tools are employed just like in milling. However, the turning method utilizes the single-point tool.

Other machining processes are. Considered to be less conventional. Although they do not use the same machine tools, they still carry out material removal processes mechanically.

Abrasive jet machining, ultrasonic machining, and waterjet cutting are examples of Non-conventional machining processes.

Conclusion

It is not enough to just decide that you want your material machine. You must put into consideration every variable in other to determine the feasibility of the process.