There are several large types of equipment powered from relatively high voltage lines. The lines exceed the 120 volts AC which is the standard in multiple homes. That said, the 240 volts AC coupled with 480 volts are usually used for large pieces of equipment like motors, large household appliances such as washers, as well as dryers. In many cases, these voltages need to be isolated electrically from the usual 120 voltages AC. Therefore, a DC contactor should be used to provide isolation. Contactors utilize the standard 120 volts power in energizing the magnetic coils. This can cause the closure of different contacts while providing power to the equipment. You can use the following tips to master the art of wiring a contactor.

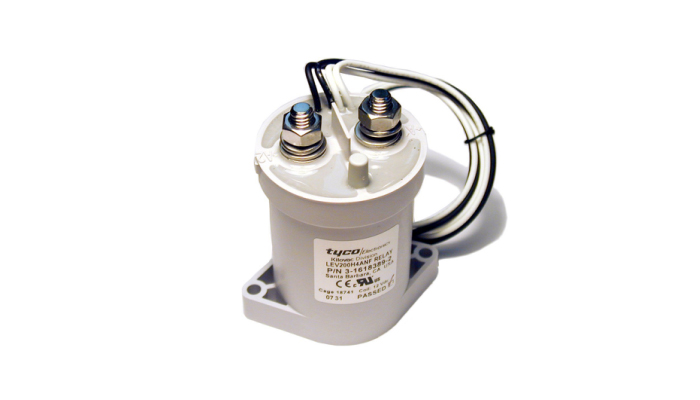

Get the contactor

It would help if you made sure that the contacts of the device are rated in voltage. You should also ensure that the contacts can handle the needed load required by the equipment that is being powered. Usually, contactors can be found from building stores and established hardware stores.

Study the manufacturer’s contact information

The information of the manufacturer will viably identify the input pins for the 120 volts AC control. There could be two sets of the output contacts identified.

Usually, these contacts can be indicated on a label as normally open (NO) and the normally closed (NC).

The two contacts can be shown as a viable drawing line from one contact ending in a single dot and another line from the contact, which is nearer the dot.

There should, however, be no contact.

Go through the auxiliary output.

Some types of contacts have an auxiliary contact as a signal to the isolated fraction of the circuit, which the contactor has energized.

The auxiliary contact is not really going to be rated at a high voltage. Instead, it needs to have a rating of 120 volts AC.

Routing of the wires

Chuck out the power to the wires and then run input as well as output wires to your contactor. The wires must have a rating by the manufacturer.

Use wire strippers to cut out the excess lengthy wires to ensure that these wires are long enough to reach their intended contact. The wire strippers can be gotten from the electric supply stores.

Strip the wires

Use the strippers in stripping the device from both ends. In case the wire is stranded, the twist is going to be exposed to the wire to ensure that the strands are not left hanging.

Over and above, you should note that the strands can make unintended contact with the equipment. This can cause viable damage.

Wire the auxiliary contacts

Using a screwdriver, loosen the screws that are holding the contact blocks in place. Then go ahead and insert these wires so that insulation is not pushed into the area of contact found in the block.

It is crucial to ensure that the strands are not jutting from the block of the contact. You can now tighten the screws found on the blocks.

Final Thoughts

There you have it from experts in the field of contactors. Many people do not know what it takes to wire a DC contactor. If you are one of them, then you should follow the steps highlighted in this blog post.