CNC machining has revolutionized the aerospace industry, emerging as the favored manufacturing method for critical components in aircraft and space exploration. This article delves into the reasons behind CNC machining’s prominence, exploring its precision, material versatility, complex geometry handling, cost-efficiency, regulatory compliance, and real-world aerospace applications. You can visit this website to get more CNC Machining Services.

Precision and Quality Assurance

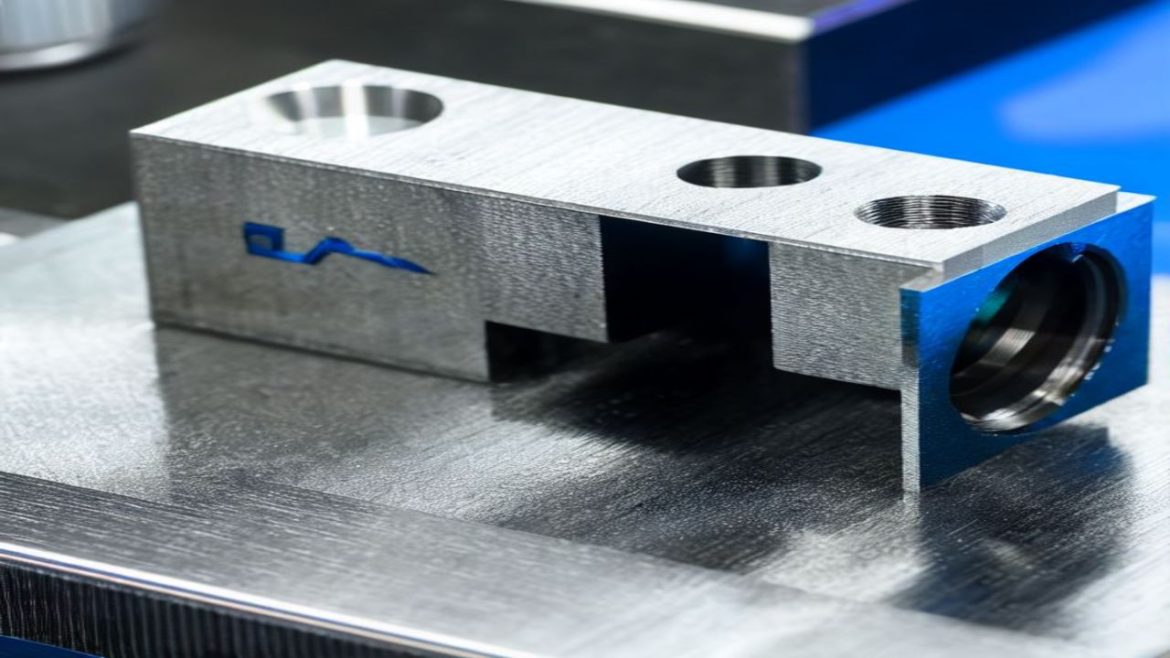

In aerospace, precision is paramount. CNC machining’s computer-controlled process ensures unparalleled accuracy, meeting the strict tolerances demanded by intricate aircraft and spacecraft parts. From turbine blades to intricate structural components, CNC machines deliver consistent results with negligible error margins. Quality assurance is at the core of CNC machining, guaranteeing every part meets aerospace standards, ensuring safety and performance.

Material Versatility

Aerospace applications require a wide range of materials, each with unique characteristics. CNC machining excels in processing various materials, including aluminum, titanium, steel, and advanced composites. The ability to work with these diverse materials makes CNC machining a versatile choice for aerospace manufacturers, who need different materials for different parts with specific performance requirements.

Complex Geometry Handling

Aircraft and spacecraft parts often feature complex geometries that demand precision machining. CNC machines navigate intricate designs with ease, producing consistent and accurate parts. From aerodynamic wing components to delicate satellite structures, CNC machining meets the challenge of complex geometries, enabling innovation in aerospace design.

Cost-Efficiency and Scalability

The aerospace industry is competitive, necessitating cost-efficient manufacturing methods. CNC machining offers economies of scale, reducing per-unit costs as production volumes increase. The same machine can produce various parts, making CNC machining adaptable to the changing demands of aerospace projects, from small prototypes to large-scale production.

Regulatory Compliance

Aerospace manufacturers face rigorous regulations and certifications to ensure flight safety. CNC machining adheres to these stringent standards, producing components that meet aviation and space industry regulations. Compliance with certifications like AS9100 underscores CNC machining’s trustworthiness in delivering reliable and qualified aerospace parts.

Real-World Aerospace Applications

CNC machining’s supremacy is evident in its extensive application within the aerospace sector. Major aerospace manufacturers rely on CNC machining for critical components. For instance, in jet engines, CNC-machined turbine blades optimize performance and fuel efficiency. Additionally, CNC machining contributes to the construction of lightweight and robust satellite structures, advancing space exploration.

Future Trends in Aerospace Manufacturing

The future of aerospace manufacturing will continue to see CNC machining play a pivotal role. Advancements in automation and AI technologies will further enhance CNC machining’s precision and efficiency. As the aerospace industry embraces innovative materials and designs, CNC machining will adapt to meet the ever-evolving demands of lighter, stronger, and more efficient components.

Conclusion

CNC machining’s dominance in the aerospace industry is well-founded. Its precision, material versatility, complex geometry handling, cost-efficiency, and regulatory compliance make it the preferred method for manufacturing critical aircraft and spacecraft components. As aerospace technology continues to advance, CNC machining will undoubtedly retain its prominent position, spearheading innovation and pushing the boundaries of human exploration in the skies and beyond. Its precision and adaptability ensure it remains an indispensable tool in shaping the future of aviation and space exploration, fueling our quest for new horizons.