The floating ball valve is the type of ball valve which aids in starting and stopping the flow of gas or fluid, especially in the petrochemical industry.

The main reason why several manufacturers often prefer the use of the floating ball valve is because of its unique and compact design.

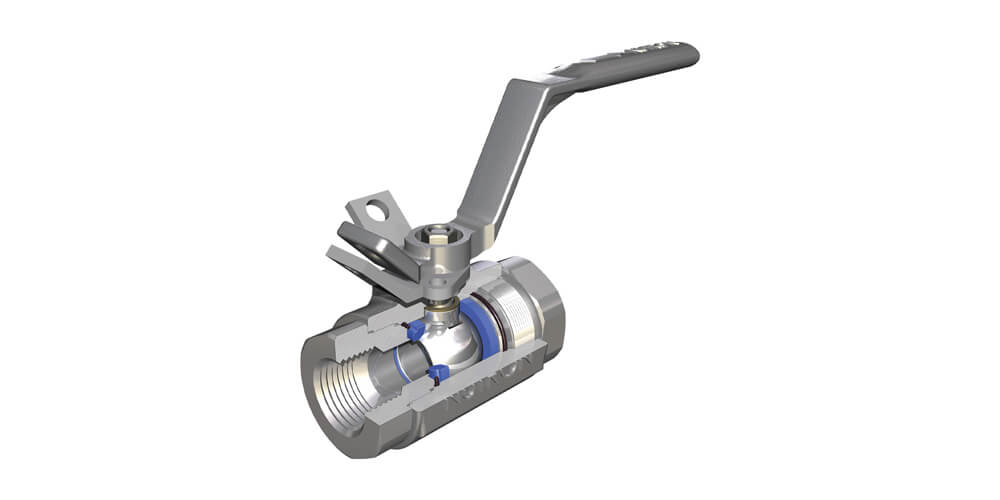

In the floating ball valve, the ball is made to suspend in the flowing fluid. This ball is then kept in compression by the presence of two electromeric seats.

Another reason why the floating ball valve is preferred the most is that it aids the bidirectional shut-off of the pipe flow.

One thing you need to know is that the main thing that leads to the high performance of the floating ball valve is the sealing design. No matter how bad it is, it seals off the lone pressure using soft seats.

How does the floating ball valve work?

The entire operation process is very simple. In the floating ball valve, the pressure of the closed valve does not act only on the upstream side of the ball, but even on the back seat. Due to the outcome of this pressure, the force pushes the ball in the upstream seat down the direction of the downstream seat.

The floating ball valve can undergo two types of deformation. The elastic deformation and plastic deformation.

The Elastic deformation is the temporary deformation using the stored energy found in the seat to improve the overall sealing performance of the valve while under pressure.

The plastic deformation of the seat is described as the permanent deformation of the seat because of certain extreme pressures.

When it comes to seating, there are different types of seating technologies, the two highly regarded seating technologies in the floating ball valve is the flexible and jam seat.

The sealing process in the floating valve is a very unique one. Upstream sealing usually occurs when the pressure does not move the ball past its current preset. As soon as the upstream pressure rises, the upstream seat moves quickly towards the direction of the downstream seat. This action will then lead to the valve being shut off.

Whenever this happens, there will be a presence of a huge gap between the body of the valve and the upstream seat.

The floating ball valve is a very unique feature that several manufacturing processes love. Because of these features, it is one of the most sought after ball valves in the word. When compared to other types of ball valves, It gives the pump the best results leading to having the best performance you can think of.

CONCLUSION.

The floating ball valve serves a lot of benefits when it comes to the process control. Unlike the Trunnion ball valve, it is easier to install and use in any of the manufacturing processes you need it to work on. If you are in the market looking for the best floating ball valve, we highly recommend you choosing from the best manufacturers.

Shanghai Datian Valve is the right company for you, especially when it comes to getting the best control valves for your processes.