If you have developed a design for the printed circuit board, you need to upload it to a specialist manufacturer for PCB prototype assembly. However, it can be challenging to choose the best manufacturer for your project. In this case, you need to narrow down the options available by making defined decisions. You need to put into account vital considerations to help choose the best PCB manufacturer. This blog will provide a guide for selecting the best PCB manufacturing company that meets your specifications.

Range of Expertise

Before you upload your PCB design to any specialist, be sure to evaluate their range of expertise. Understanding the services a PCB manufacturer offers will help assure you of the quality you expect for your project. In that case, ensure you confirm whether the manufacturer assembles rigid, flex, or rigid-flex circuits for both single and multiyear. Besides, find out if the manufacturer works with a wide variety of PCB materials. Check the client base to get the details about the experience and knowledge of the manufacturer to get comfortable working with the experts.

PCB Quality

When choosing a PCB manufacturer, quality is the first thing to consider. It would help if you looked at different aspects to ensure the overall manufacturing process meets industry standards. Quality of the PCB means no errors in the assembling process. Keep in mind that any mistakes can endanger electronic devices. Therefore, the manufacturer should be able to meet all requirements. These include using suitable material, accepting the ideal file formats, and producing boards that perform optimally.

Customer Service

Customer service is essential when you intend to work with a particular PCB manufacturer. Ensure that communications channels are beyond phone availability and online chat when you need quick responses. Be sure to choose the manufacturer that provides reliable options to choose when it comes to vital aspects of your project. Check if they offer online quoting or evaluate your design to ensure it meets the design rules before assembling. A reputable manufacturer will do everything to provide the necessary support to ensure your design functions properly and boost the overall performance.

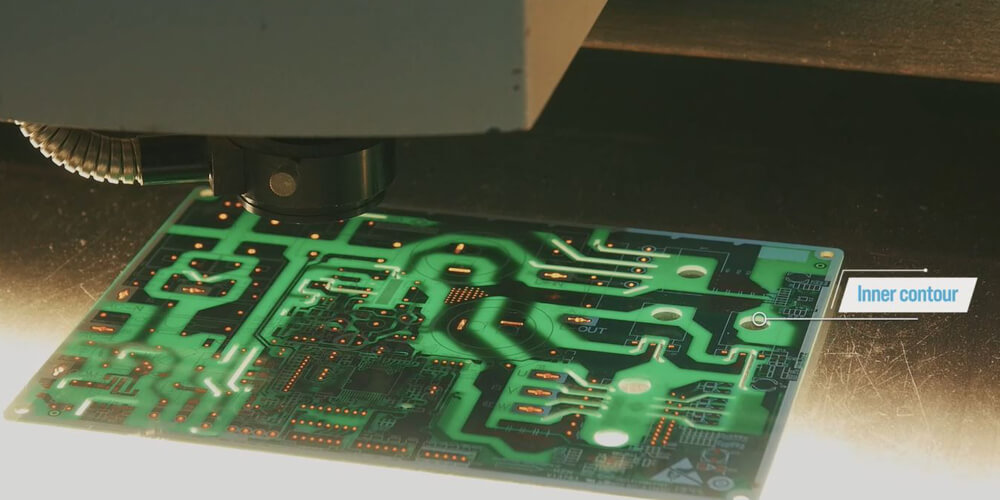

Essential Components and Lines of Production

Before choosing a PCB manufacturer, you need to check the essential components required for the assembly process. On the other hand, ensure they have their lines of productions, especially when you have a large number of products to the manufacturer. Find out how fast the manufacturer can produce multiple orders simultaneously and supply your order. Similarly, there should be a diversity of parts and units that can be used to optimize the performance of your boards.

Proper Storage

Printed circuit boards require special storage no damages to the circuit continuity. Ensure that the company follows the correct storage protocol for the PCB component and the circuit boards when delivering your order. The packages should be appropriately sealed using vacuum seals to eliminate damages that result from humidity or high temperatures. Similarly, the packages should also have silica gel to eliminate any moisture to ensure that the essentials are not affected when oxidation comes into play when they are exposed to air.