Electromechanical buzzers can look similar at their simplest without the bell or hammer and the buzzing sound created by the relay contacts which are amplified by the attachment to a sounding board of some form.

An electric buzzer makes repetitive sounds and it makes use of electromagnet to achieve this. Buzzers cause an electromagnet to vibrate a metal disc by supplying it with oscillating currents. They require drive current to provide this current and it is usually built in the device.

They are usually of single tone and are usually rated either by 6 or 24 volts. Electric buzzers can be used for alarm circuits, timing, timing, and control, test equipment. To achieve this device maximum sound, it should be mounted firmly

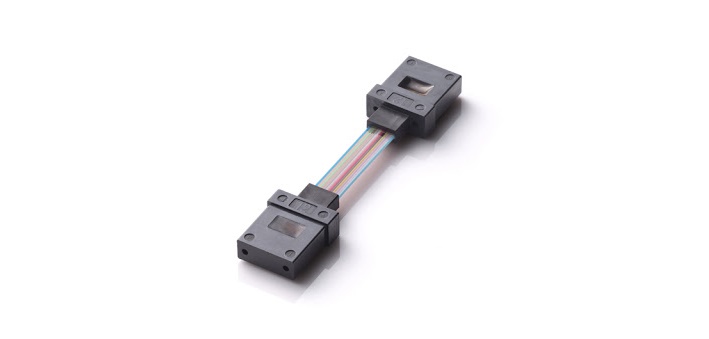

Types of SMD Magnetic Buzzer

- 12 by 12 x3mm Ac 3V 5V 12V SMD buzzer

This product has a rated voltage of this product is about 3.0 Vp-p. It has an operating volt of 1.0-20.0Vo-p. Its current consumption is about 5mA maximum with a capacitance of 16000±30%PF. Its sound output is 75/10cmbBA. It has a resonant frequency of 4.0±0.5KHz. The operating temperature is -40-+85°c while the storage temperature is -40-+85°c. It has a dimension of 12.0*12.0*H3.0mm. It weighs 0.5grams and the material used is black LCD. The terminal is SMD type and its storage life is for 6 months. The environmental protection regulations are RoHs

- 8030 x 8.5 by3mm 3v SMD buzzer

The 8030 x 8.5 buzzer has an oscillation frequency of 2731Hz with an operating voltage of 5~ 4.5 Vo-p. Its rated voltage is 3.6 Vo-p and its consumption current is 100mA. Its sound pressure level is 86dB. It has a coil resistance of 16±2.4Ω. Its operating temperature is -20 ~ +60°c while the storage temperature is -30 ~ +80°c. It has a dimension of 8.5 x 8.5 x H3.0mm. It weighs about 0.8grams. The material used is LCP black. It is plated with brass and the environmental protection regulation is RoHs.

- SM04ET02A 3V 4000HZ SMD buzzer

It has an oscillation frequency of 4000Hz Vo-p=1/2duty, square wave. Its operating voltage is 2 ~ 4Vo~p with a rated voltage of 3Vo~p. It has a current consumption of 90mA with a sound pressure of 70dB. It has a coil resistance of 17±3Ω. The operating temperature is -20 ~ +70°C with a storage temperature of -30 ~ +80°C. It has a dimension of 4.0 x 4.0 x H2.0mm and it weighs about 0.01gram. The material used is LCP black. It is played with brass and the Environmental Protection Regulation is RoHS

- MSPS43A 12v 43mm outdoor piezo buzzer for a fire alarm system

Its model number is MSPS43A28220 with an Operating Voltage of 60~250VDC/AC. Its Tone Nature: FAST PULSE and the maximum rated current is 16mA at 220VDC/AC with a minimum sound pressure level of 91dB at 220VDC/AC 10cm. Its resonant frequency is 2.8±0.5KHz. It has an operating temperature of -20℃~+60℃ and a storage temperature of Storage -30℃~+70℃. It weighs about 43g.

- 1203 SMT 4000HZ PIEZO BUZZER WITH 80DB piezoelectric SMD

It has an operating voltage of 1.0-20.0Vo-pV and its maximum rated current is 3mA. It has a minimum sound output at 4.1 kHz/10cm: 75dB. Its resonant frequency is 4000±500Hz with a capacitance of 16000±30%pf at 120Hz. Its operating Temperature is -40~+85°C while storage temperature is -40~+85°c. It weighs about 0.5g and its housing material is LCP black

Final Thoughts

Are you looking for manorshi SMD magnetic buzzers? Following that link will surely lead you to the right place. We hope you find what you’re looking for!