Strong and dependable materials are crucial in the construction of today’s cutting-edge infrastructure. Pipes made from AS1163 C350 China Manufacturer structural steel are essential to the development of our modern water and power systems. The strength, durability, and adaptability of these pipes, as outlined by the AS/NZS 1163 standard, is crucial to preserving the reliability of infrastructure.

Strength and Structural Integrity

The construction of water and electrical systems necessitates the use of resilient materials capable of withstanding extreme conditions. AS1163 C350 pipes are highly reliable due to their minimum yield strength of 350 MPa. The weight of water distribution networks, power lines, and other infrastructure won’t distort their form or affect their functionality. Their cold-formed design guarantees consistency and dependability in a variety of load-bearing contexts.

Corrosion Resistance

Corrosion presents one of the greatest obstacles in building infrastructure. Traditional materials can degrade over time when exposed to water and chemicals. Coated or galvanized AS1163 C350 pipes have exceptional corrosion resistance. For utilities like water and power, where reliability is crucial, this is a must. The pipes’ resistance to rust and degradation greatly increases the dependability and lifespan of these critical infrastructures.

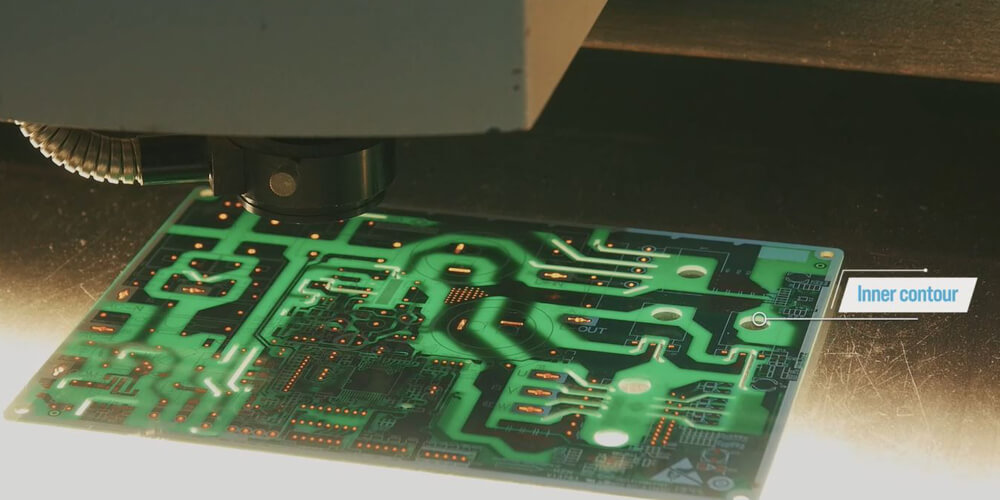

Fluid Transport

Fluids must be transported without interruption in water and power systems. The exact measurements and smooth interior surfaces of AS1163 C350 pipes make them ideal for this purpose. These qualities allow for the smooth passage of fluids without any obstructions. The uniform and unimpeded paths provided by these pipes improve the overall performance of the infrastructure, whether they are transporting water for consumption or electricity for distribution.

Ease of Installation

Infrastructure projects rely heavily on construction efficiency. The installation process is simplified greatly with AS1163 C350 pipes. Their standard size and light weight cut down on the time and effort required for installation. Water and power infrastructure projects, which must be carried out precisely and within strict time constraints, benefit greatly from this.

Environmental Considerations

Sustainable development principles should inform today’s infrastructure. The recyclable and long-lasting nature of AS1163 C350 pipes helps achieve these goals. Because of their long service life, infrastructure maintenance and upgrades have less of an effect on the environment than they otherwise would. Responsible resource management is mirrored in the selection of eco-friendly building materials like these pipes.

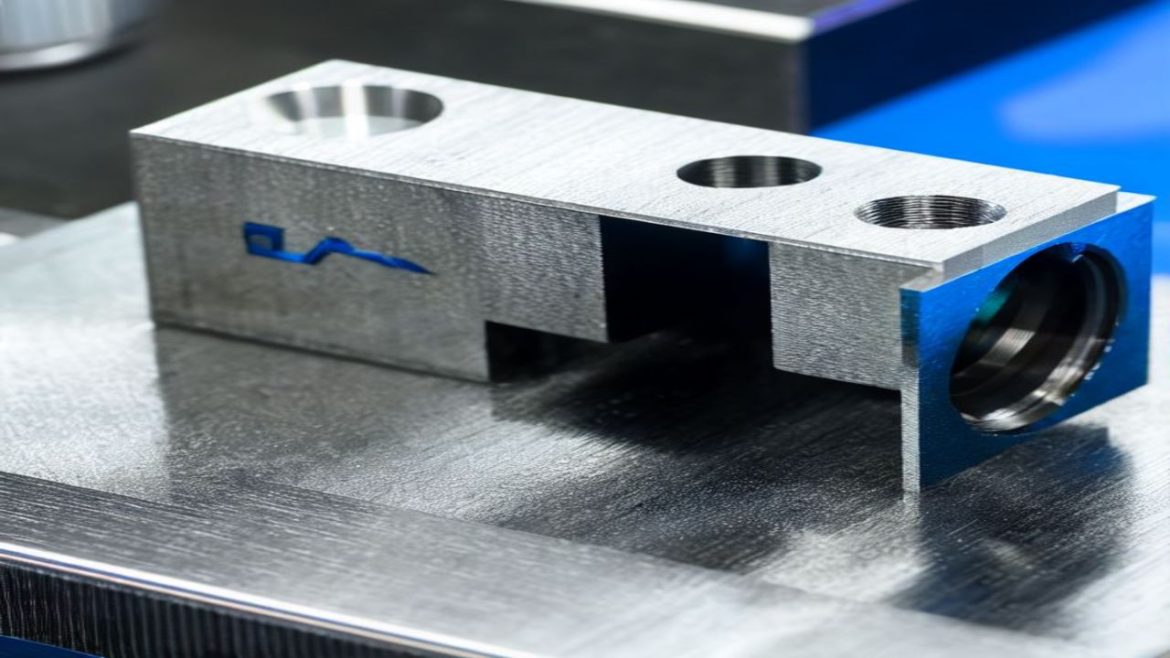

Versatility in Design

AS1163 C350 pipes are an adaptable option for numerous applications in the water and power supply industries. They can be used for a wide variety of purposes, from pipelines to support structures, thanks to their flexible layout. Engineers and architects can now design infrastructure that meets their specific needs in terms of efficiency, performance, and security.

Conclusion

The importance of material engineering in shaping the water and electrical infrastructure is exemplified by AS1163 C350 pipes. The foundation of dependable and resilient systems, these pipes impress with their strength and resistance to corrosion, as well as their ease of installation and positive effects on the environment. The role of AS1163 C350 pipes in ensuring the continued functionality of water and electricity networks is indispensable as infrastructure projects evolve to meet the demands of growing populations and changing environments.