In relevant industries, the use of CNC machining has proven to be very important for optimum industrial productivity. CNC stands for Computer Numerical Control. The CNC Machine relies on a lot of computer programming for its control and use.

Because of the efficiency of this machine, it has been adopted by a lot of computers and it has been used to achieve great results industrially.

There is one company that has stood the test of time when it comes to the provision of the best CNC machining China services. 3ERP is a company that provides you with a lot of CNC machining services that you can think of.

We are a company that is capable of handling all your technical difficulties with ease. The only thing you need to focus on is your entire production process. All you need to do is to trust us to give you the right job whenever you want.

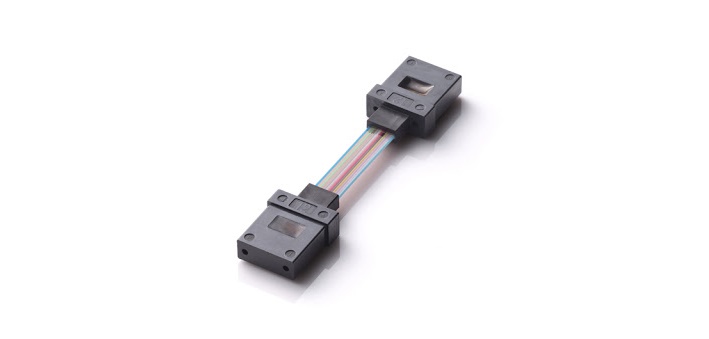

In the glass cutting and machining industry, the use of CNC machining is very important when it comes to achieving great and accurate results. The CNC machine delivers high precision and accuracy for customers.

In the remaining parts of this article, we will do our best to show you the important parts of the CNC Machine and why it is important.

We are a company that offers quality at all times. The main reason why a lot of people love us and our brand is that we do not compromise on the quality of our machines.

Benefits of working with 3ERP.

- We have the experience.

In our company, we take a lot of time to train our engineers for every task they are going to face. All our staff is equipped with the best technical knowledge and for each project, our experience and technical knowledge keep getting stronger.

We invest in our team regularly to keep them abreast of the latest trends in technology so we can serve you better.

- We have advanced technological processes.

One of the things that made our customers love us always is the way we handle our business to give you the best results. All our technical and manufacturing processes are unique and advantageous to give you the best in accuracy and precision. Your machined parts would be handled with care and given to you to your satisfaction.

- Our delivery processes are the best.

We have hardly seen a company with a faster response and delivery time like ours. We have a delivery process that beats our competition at all times. We deliver on time and most importantly, in good conditions.

When you opt-in for our CNC Machining China, you are going to get the best from us.

Conclusion.

We deliver the best CNC Machining services to all our customers. If you are looking for the CNC services expert, you can always count on us to give you the right job.