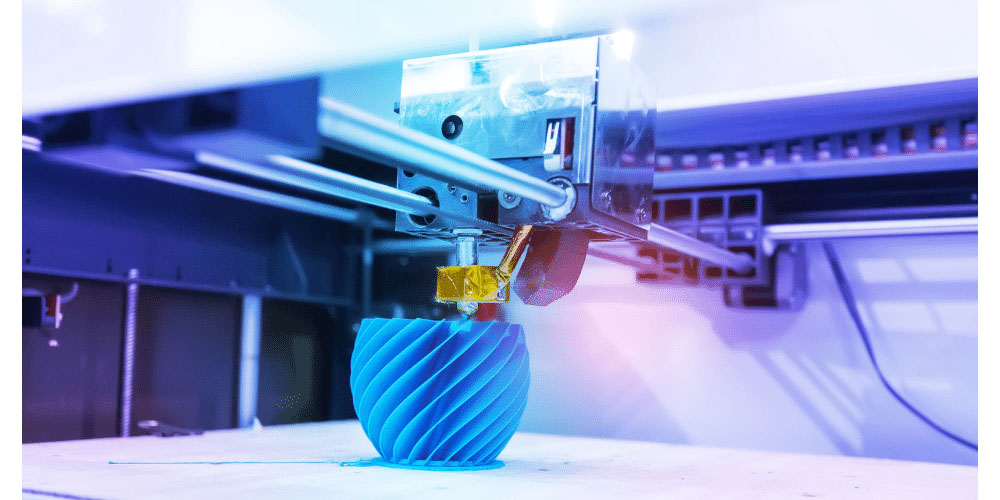

3D printing also goes by addictive manufacturing. The 3D printing manufacturing procedure involves building several layers of a part, each at a time. The 3D printer works by receiving information from a computer. After it has received the information, the 3D printer works by hardening or depositing material in the way that the computer has programmed it to; therefore, successfully creating layers. 3D technology has changed the way manufacturing works. It allows companies to acquire parts instantly. In addition, 3D printing allows for rapid prototyping. There are several advantages to acquiring the services of a rapid prototyping company. This post aims at informing you of the five main advantages of outsourcing 3D printing services.

5 key advantages of outsourcing 3D printing services

1. Affordable

3D printing is a very affordable service to acquire. In the manufacturing procedures, 3D printing does not require any form of tooling. Therefore, the only thing used is the chosen material. The fact that the process is not complicated is what makes it a very cheap service to acquire. In addition, 3D printing is suitable for small batches and one-off parts.

2. Get any shape you want

3D printing is computer-controlled. Therefore, it creates a layer at a time. The fact that the 3D printer operates under computer control ensures that you can get shapes in whatever geometry you need. In addition, 3D printing allows for the printing of very complex parts. The complex printed parts are not only on the exterior but also on the interior.

3. Efficient

3D printing uses CAD software. Therefore, one of the best advantages of acquiring 3D services is that it is very efficient. 3D printing allows no room for error. The output will be a replica of the design. Also, the production time is very little. You can get your parts in just a few hours; this is made possible because of the lack of tedious setup processes.

4. Adaptable

3D printing does not require the use of any tools for it to complete its processes. Therefore, the risk of creating parts with errors is very minimal. But, if there are some little errors present, you can quickly correct them digitally. Furthermore, you do not need to purchase new tools. The adaptability feature of 3D printing is among the best of the advantages that it offers.

5. Environmental elements

One of the best advantages of using 3D printing is that it involves no material wastage. You can be 100% sure that there will be no waste of materials like other machining services. Therefore, the materials saved can mean a reduction in the environmental pollution in discarded wastes.

Conclusion

3D printing has changed the way manufacturing works. It has brought with it many benefits that allow for the smooth running of business operations. Businesses outsourcing 3D printing services do not have to wait for very long before the outputs of their products are developed. In addition, 3D printing can be used on both metal and plastics to produce prototypes. The many advantages of 3D printing make it a precious service to source. The assurance of quality and efficient output also makes it very popular.