Molecular weight is one of the pillars of chemistry. However, it can be quite hard to grasp. Most people use calculators designed specifically for calculating molecular weight to make things easier.

While this is no doubt a brilliant plan, it is always important to understand molecular weight better and how it works. That is why we are here. Today, we will be discussing molecular weight and the various way to calculate it better.

What Is Molecular Weight?

This refers to the addition of values of the weight of atoms that are present in molecules. The weight of these measurements are used mostly in chemistry. Most times, molecular weight is simply referred to as MW. They can also be called M.W

If you are interested in molecular weight, you will no doubt have found the similarity in molecular and atomic weight. The main similarity is in the way they are both measured. Their measurement is done in relation to isotope-carbon’s mass. This mass is usually assigned to a particular value. Usually, it will be 12 amu.

The atomic weight does not exactly last on this assigned value. Its mixture of isotopes and carbon makes this impossible.

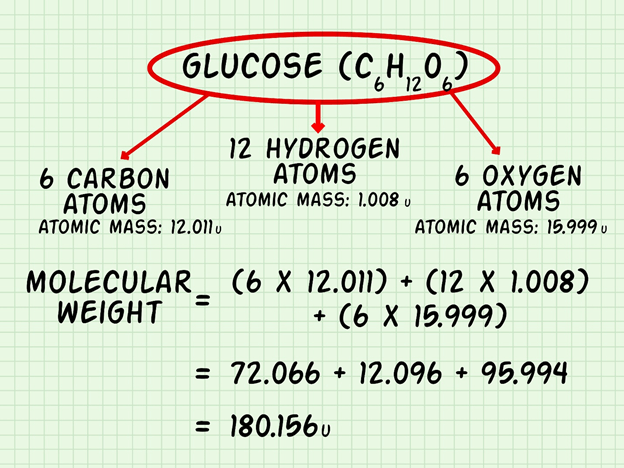

How is molecular weight calculated?

Just like most equations and elements, the molecular weight followed a particular pattern. The calculation will usually be done using a compound. Please remember that the compound here does not necessarily mean that it must be at its most basic form.

Each atom is grouped according to types. these types are multiplied by their particular weight. After this is done, the figure gotten is added to the weights of the other atoms present.

How to determine the molecular weight

The determination of the molecular weight will depend on a number of factors. One of these factors includes the size of the molecule being weighed. One of the more popular ways used to calculate the mass of molecules is called mass spectrometry.

However, if the molecule is larger and has a mixture of protein, then the molecular weight will have to be calculated differently. The usual calculation will involve using viscosity or light scattering.

It is important to note that calculating the molecular mass and weight is two different things. When molecular mass is used, it usually refers to the mass of the molecular itself and not the weight. The weight of a molecule refers to the force that acts on the mass of a molecule.

While most persons use these terms freely and interchangeably, it is always a good thing to keep these differences in mind.

The easiest way to calculate molecular weight

While the calculation can be understood, calculating the molecular weight itself can be quite stressful. MW calculators are readily produced to make this less stressful.

The best part is these calculators are online and can be used quite easily. If you have to keep tabs on the weight of molecular mass for business’ sake, then make sure you have an MW calculator handy at all times.